Environmental Policy of GIKIL

Our goal is stable and sustainable development. Environmental protection benefits everyone:

Our communities, customers, employees and future generations, and thus:

We have defined and implemented environmental objectives and processes by applying all legal provisions to protect the environment;

We are committed to avoiding and reducing emissions and remain compliant with the BAT while conserving natural resources.

We are continuously working to improve our production processes and product quality.

We apply technological innovations in an ecologically efficient way.

We strive to reduce the generation of waste, collect it selectively and develop environmentally friendly waste disposal methods.

We raise the environmental awareness of our employees to enhance our company’s environmental value.

We are continuously committed to improvement of our knowledge and management through training and further education of our employees.

We constantly strive to improve environmental protection management, regularly monitor and review the environmental protection management system to ensure its effectiveness.

Environmental Policy of GIKIL d.o.o. Lukavac provides a framework for setting and confirming operational objectives and is aligned with the organizational context.

Senior management will regularly review the effectiveness of the environmental management system and environmental objectives to ensure their effectiveness and continued applicability.

All employees have a responsibility to work in an environmentally acceptable manner to avoid any harmful effects of their work on the environment.

With regard to air protection and atmospheric emissions, in recent times maximum attention has been paid to technological improvements in the production of raw coke gas and coking ovens.

In addition to improving technical accuracy when selecting coal blends, it is very important to have regular and unscheduled crusher overhauls for precise grinding of the blend, coke ports and ducts, as well as firewall replacement. In addition, an overhaul of the charging machines was carried out for the proper filling of the coking ovens, as well as a general overhaul of the coke gas suction system.

Repairs to the damage to the coke oven walls of the V-Coke Battery are underway and management has decided to replace the battery’s complete platform.

Wall repair includes coke oven ceramic welding. Apart from the fact that it is a very complex and demanding job done at very high temperatures, the refurbishment is progressing well and about 50% of the work is already completed. All chambers, or ovens, will be renovated in this way before the end of the year. In addition, besides replacing the entire platform, it not only extends the active operation of the battery and makes better use of the coke extraction process, but above all contributes significantly to reducing harmful emissions which is the most important goal.

Slika 1.Keramičko zavarivanje koksne peći

Slika 1.Keramičko zavarivanje koksne peći

Additional coke battery production and environmental improvements will be achieved early next year when two new machines will be installed

This is a smokeless charging machine and a coke receiving machine that didn’t work before. With new machines, there will be no more waste or emissions. They have been ordered and are currently in production, the commissioning deadline is February 20th and their commissioning is scheduled for February 2023. All this is not only for the purpose of improving production processes and techniques, but also to reduce uncontrolled emissions into the atmosphere.

Slika 2. Mašina za bezdimno punjenje uglja

Slika 2. Mašina za bezdimno punjenje uglja

Significant reductions in air pollutant emissions have also been achieved by terminating activities at the Power plant. A completely new gas line was put into operation to supply gas to the boilers. Smoke duct, burner casings, combustion chambers, sieve tubes were replaced, walls around burners were repaired, external air fans and walls were repaired, and boiler desludging was carried out. A new water heater, economizer and air heater were installed in the chimney to improve combustion in the boiler and reduce emissions.

The PLC control system was also replaced, achieving improved regulation, air heating, the possibility of adding more air to the burner and a better gas-air mixture, better combustion formation which reduces emissions into the air.

Slika 3. Novi dimni kanal

Slika 3. Novi dimni kanal

There are currently no emissions or pollution from the Fertilizer plant, specifically since October 2021, when the Management decided to temporarily suspend the operation of the Fertilizer plant.

The decision was made solely due to the cessation of production caused by long-term economic and financial consequences and realized losses. All labour force is retained and distributed to other plants and departments.

On the other hand, at the maleic anhydride plant, the catalyst has been replaced and the compressor has been overhauled, and new investments are underway.

Slika 4. Čišćenje starog katalizatora

Slika 4. Čišćenje starog katalizatora

Replacing the catalytic converter significantly reduces the concentration of carbon monoxide in the exhaust gas. Here it is worth mentioning that the project to reduce the concentration of xylene in the exhaust gas is expected to be implemented by the end of this year.

Slika 5. Ubacivanje novog katalizatora

Slika 5. Ubacivanje novog katalizatora

Replacing the catalytic converter significantly reduces the concentration of carbon monoxide in the exhaust gas. Here it is worth mentioning that the project to reduce the concentration of xylene in the exhaust gas is expected to be implemented by the end of this year. Another major investment is underway in this plant. This involves purchasing a new reactor that will further reduce harmful emissions into the air. At the same time, we are completing the technological process related to wastewater treatment technology at AMK plant.

Special care is taken to avoid ground emissions and harmful effects on the ground. Following the success of the land remediation project, the bio-recovery potential of areas devastated by industrial waste was explored with the help of the Cantonal Ministry of Spatial Planning and Environmental Protection and other participants.

6. Remedijacija industrijske zone fabrike Koksa

6. Remedijacija industrijske zone fabrike Koksa

The project was carried out with the support of the Federal Ministry of Education and Science, after which more than 500 saplings of silver spruce, red maple, white and black pine, Paulownia elongata and other flowers were planted within the entire GIKIL complex.

One of the main activities that we quickly carried out at Global Ispat Koksna Industrija d.o.o. Lukavac in the past time is implementing projects to prevent and reduce the emission of harmful substances into water, as well as protect water sources in general.

For the collection of technological, precipitation-polluted, and sanitary-faecal wastewater, as well as for their purification and disposal, all technical-investment paperwork has been completed at the level of main, implementation projects. A separate sewage system is specified in the project documentation.

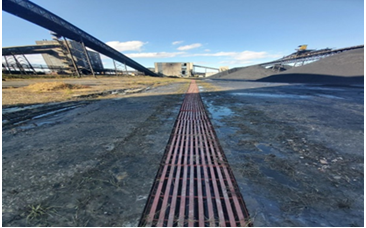

At the coking and coal storage depots, gravity filtration equipment has been built. All are working and delivering the required results.

Slika 1. Izgradnja gravitacionih taložnika

Slika 1. Izgradnja gravitacionih taložnika

The most important aspect is that the cleaned sediment is returned to the landfill and used as a raw material in the production process. In fact, the suspended solids in the primary sediment are particles of coal and coke. As a result, there is no discharge or overflow into other flows and the specified limit values are met.

.

Slika 2. Izgradnja gravitacionih taložnika

Slika 2. Izgradnja gravitacionih taložnika

The physicochemical and biological wastewater treatment optimization project is the only facility of its kind in the field and one of the largest and most important ongoing projects

Slika 3. Izgradnja objekta za fizičko-hemijski i biološki tretman otpadnih voda

Slika 3. Izgradnja objekta za fizičko-hemijski i biološki tretman otpadnih voda

The purpose is to ensure the limit values specified in the Ordinance on conditions for discharge into the environment and public sewers..

Slika 4. Završen objekat za fizičko-hemijski i biološki tretman otpadnih voda

Slika 4. Završen objekat za fizičko-hemijski i biološki tretman otpadnih voda

Based on the input parameters, the performed analyses and the required output parameters of the purified water, the optimal solution is predicted the optimal solution to obtain pure water from the technical wastewater after going through all the processes.

Slika 5. Instaliranje opreme za tercijal

Slika 5. Instaliranje opreme za tercijal

Slika 6. Instaliranje opreme za tercijal

Slika 6. Instaliranje opreme za tercijal

A sludge storage tank and a sludge dewatering device are also installed.

Slika 7. Dehidrator za mulj

Slika 7. Dehidrator za mulj

At the same time, a project was completed to collect tar condensate from the Coke plant gas pipeline, to be transferred to the tar pumping station and then to the existing physicochemical and biological treatment at the Biology plant.

Slika 8. Projekat prikupljanja katranskih kondenzata sa plinovoda

Slika 8. Projekat prikupljanja katranskih kondenzata sa plinovoda

The same was done not only at the Power plant, but also on the gas pipelines of defrosting hall, separation and biology, while grease and oil separators were installed at the Benzene plant and at the gas holder at the Coke plant which also provides the required results.

Slika 9. Ugradnja separatora masti i ulja

Slika 9. Ugradnja separatora masti i ulja

Activities have also been initiated to implement, collect, treat and discharge industrial wastewater from the Power plant. The necessary pipes and inspection shafts were procured. Since these works are also widely implemented in the field, the effect will soon be visible.

Slika 10. Radovi prikupljanja, tretiranja i ispuštanja tehnoloških otpadnih voda

Slika 10. Radovi prikupljanja, tretiranja i ispuštanja tehnoloških otpadnih voda

At the Filter Station, the quartz sand was replaced in the sand filters and the anti-corrosion protection was completed.

At the same time, the preliminary and main project to collect, treat and discharge industrial wastewater from the filter station was completed. This is one of our larger and most important projects, along with the project for water license. The works have already started and we will see immediate effect as this will prevent suspended solids from entering the Jala River.

Slika 11. Izgradnja postrojenja za prikupljanje, tretiranje i ispuštanje tehnoloških otpadnih voda sa filterskog postrojenja Modrac

Slika 11. Izgradnja postrojenja za prikupljanje, tretiranje i ispuštanje tehnoloških otpadnih voda sa filterskog postrojenja Modrac

The treatment and use of disposal of waste is carried out according to the provisions of the Law on Waste Management and the Waste Management Plan. Waste monitoring has been established, the place of its generation has been located, and register of waste by type, quantity, treatment method and transportation are kept properly.

Slika 1. Upravljanje otpadom

Slika 1. Upravljanje otpadom

In addition, the construction and equipment project for the hazardous waste and other waste storage plant was implemented to ensure storage conditions, in accordance with the law provisions.

Slika 2. Skladište opasnog otpada

Slika 2. Skladište opasnog otpada

Another novelty is that the entire GIKIL complex collects and sorts five types of packaging, wood, scrap paper and cardboard, in cooperation with the local community, namely Lukavac’s schools and citizens’ associations to which all these are donated. All this implies that the company is in the midst of major transition and major changes and that we want to show our social responsibility as much as possible, all with the aim of preserving the environment.

Slika 3. Razdvajanje otpadnog materijala

Slika 3. Razdvajanje otpadnog materijala

We are actively working to spread awareness among employees, customers and suppliers about the environmental aspects of GIKIL, with permanent openness to the public whenever they are interested.